Challenge

The objective was to realize the client’s vision of a next-generation greenfield pharmaceutical facility with fully automated sample and goods management, covering storage, transport, digital integration, and delivery across the building.

The program involved designing and deploying a first-of-its-kind solution in a highly regulated GMP environment. No off-the-shelf system existed that could meet the combined requirements of robotic transport, multi-temperature sample handling, digital traceability, and hybrid GxP / non-GxP use. The solution therefore had to be designed from scratch, including processes, workflows, and system architecture.

Key challenges included the integration of multiple robotic systems (AGVs), automated storage technologies, building infrastructure, and existing laboratory IT systems (e.g. LIMS), none of which were originally designed to operate together. Temperature constraints added further complexity, requiring coordination between ambient transport and multiple controlled storage environments.

The program also involved a large number of stakeholders and suppliers, spanning laboratory users, quality, engineering, IT, and automation partners. Change management was critical to align laboratory practices, labware, and operational workflows, while ensuring full GMP compliance, traceability, and inspection readiness throughout the deployment.

Solution

NEVESO assumed end-to-end program leadership, providing on-site project management, engineering, and robotics expertise. Acting as the central integrator, NEVESO structured and coordinated the entire delivery, from concept definition through design, implementation, qualification, and operational handover.

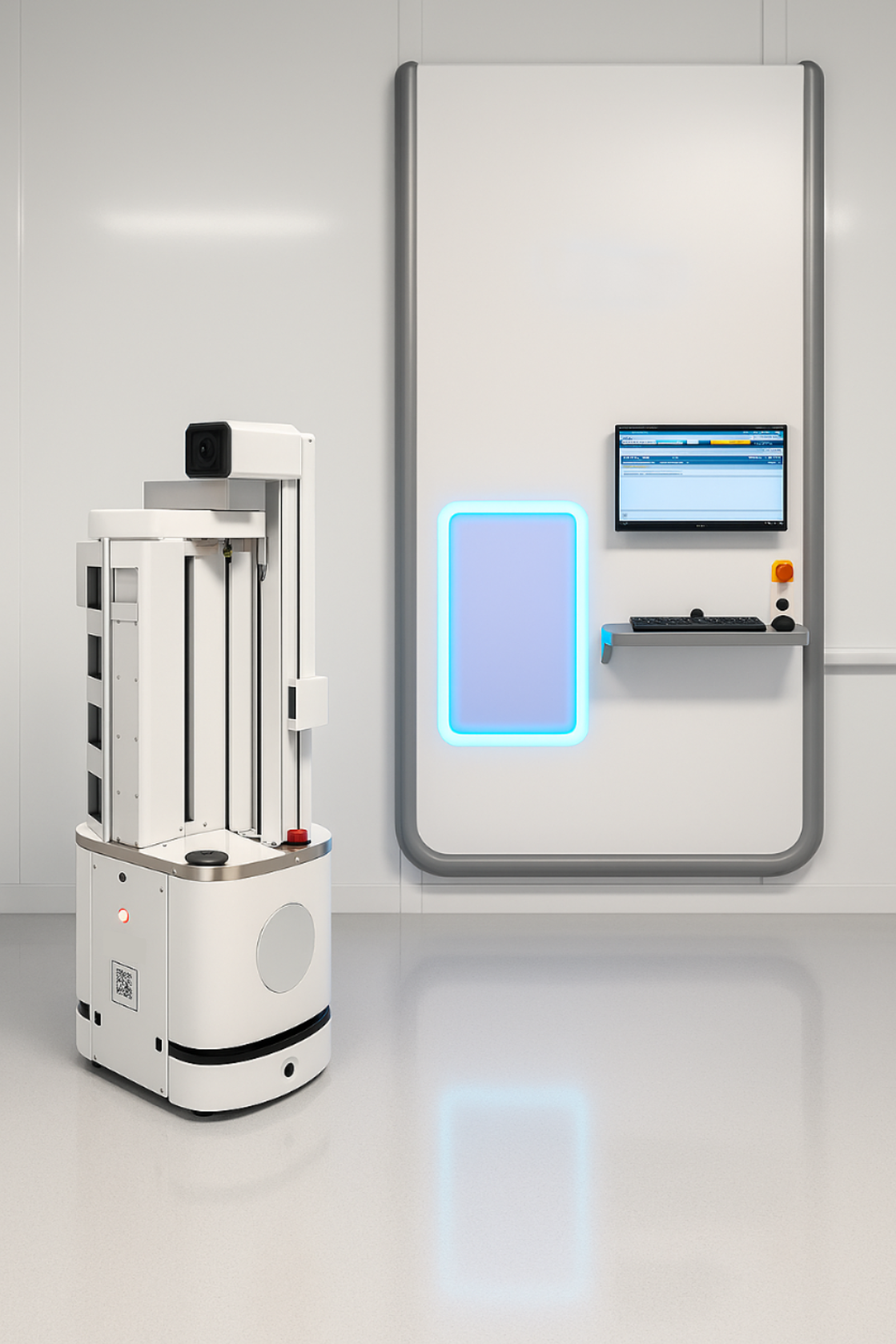

The engagement started with the definition of the global automation vision and system architecture. NEVESO identified and co-developed Commercial Off-The-Shelf (COTS) robotic solutions adapted to GMP constraints, deploying dedicated AGVs for sample transport and AMRs for intralogistics. A dedicated digital infrastructure was designed and implemented, enabling

transport orders, system orchestration, and full sample traceability through API-based integration with existing laboratory systems.

In parallel, NEVESO designed all processes and workflows from scratch, including a robust strategy for hybrid GxP / non-GxP operation. This included segregation concepts, qualification strategy, compliance documentation, and validation protocols, ensuring the system was GMP-qualified without limiting operational flexibility.

NEVESO also established program governance covering planning, CapEx control, supplier management, and stakeholder coordination. A key component of the solution was the creation and training of a new on-site robotic competence center, enabling the client to fully operate, maintain, and further develop the system in the long term. Close collaboration with the client supported internal communication, external presentations, and the promotion of the solution at group level.

Business Impact

-

Successful delivery of a fully automated sample and goods management system valued at over CHF 4 million

-

First-of-its-kind GMP-ready robotic sample management solution, designed and delivered end-to-end by NEVESO

-

Full digital traceability with real-time tracking, audit trails, and validated workflows supporting GMP compliance

-

Hybrid GxP / non-GxP operation enabled within a single qualified system

-

Measurable site-level benefits, including improved productivity, reduced human error, optimized FTE allocation, and simplified day-to-day laboratory operations

-

Group-level impact as a reference innovation for future laboratories, strengthening the client’s innovation image and enabling awards recognition (including Raya award)

-

Establishment of a sustainable robotic ecosystem on site, with continued NEVESO support to extend and continuously improve the system

-

Successful realization of a strategic vision, redefining sample and intralogistics management and opening opportunities for global deployment across the organization or other clients.